Checklist: 10 Questions Industrial Designers Need to Ask About Injection Molding

There are ten key questions designers must have the answers to for a successful conversion from other materials to resin injection molding. Whether the design is for medical devices, business machines or for an industrial application, arm yourself today with this valuable infographic checklist.

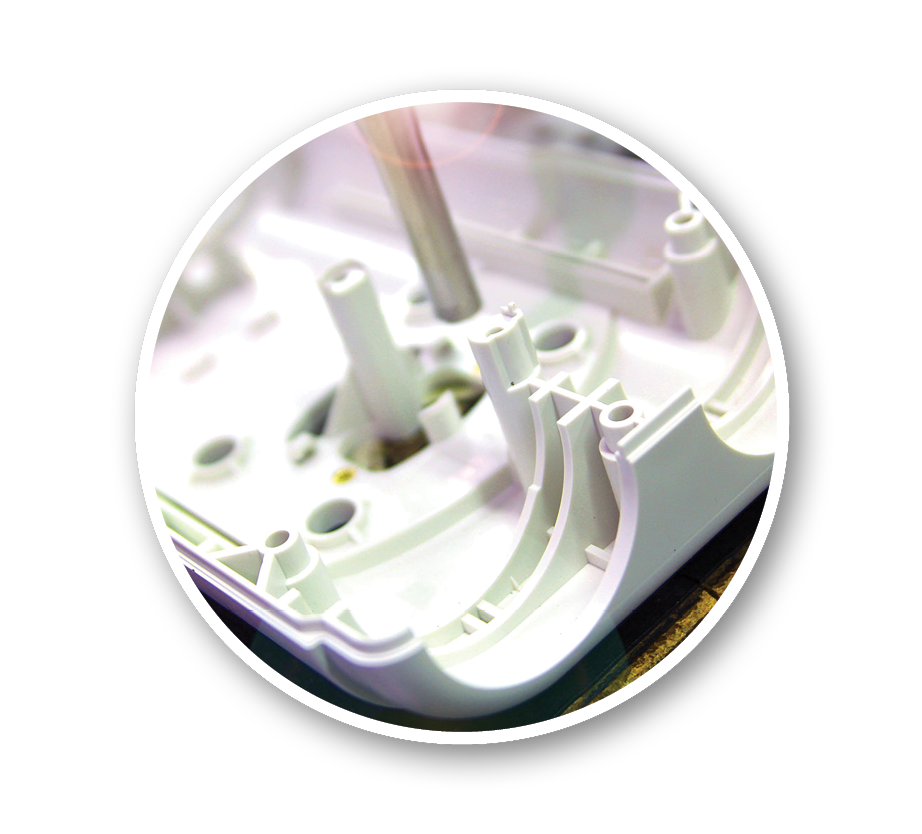

Injection molding is a highly-engineered process whose demand continues to grow as more manufacturers replace traditional materials like wood, steel and fiberglass with thermoplastic resins that are lighter in weight, but just as durable. Applications and uses for injection molded parts are numerous and growing, with increased demand from the medical, automotive, industrial, housewares, electronics and many more industries.

If you're thinking about a conversion to resin injection molding, you may have critical questions about the quality of the finished part. But designing the right part-and choosing the right injection molding partner-require a thorough understanding of 10 core questions you need to ask.

Where is this part going to be used?

Is the part a stand-alone product or a piece of a larger assembly or system? Does it have to stand up under heavy loads or is its appearance important?

Industrial or consumer?

Understanding the industry and how the end-user will ultimate interact with the part, if at all, will impact your design and the materials you select.

When is the right time to bring in my molding partner?

Understanding the industry and how the end-user will ultimate interact with the part, if at all, will impact your design and the materials you select.

Who owns the final part design and the tooling?

The answer should always be: you.

Does the molding supplier have experience in the relevant industry?

Can the injection molder meet your project's deadlines and milestones?

What's the right molding technology for you to consider?

What's the right resin material to select?

What part geometry and specs are you designing to? Strength, temperature, appearance, chemical resistance, etc.?

What compliance bodies and certifications do I have to design to pass?